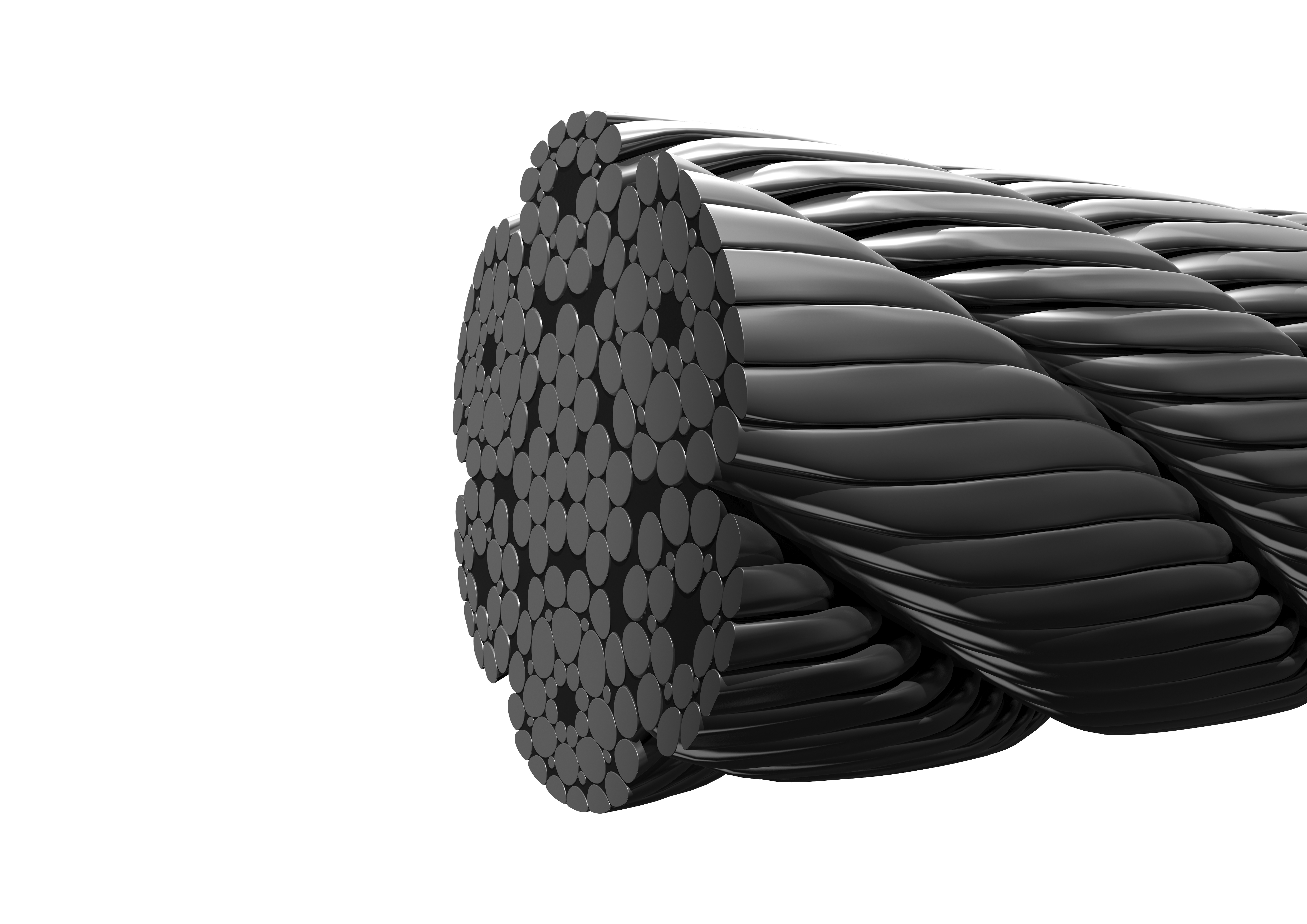

This swaging process reduces the rope diameter and reforms the profile of the outer strands providing a rope that performs excellent in multilayer drum applications.

Bridon constructex wire rope.

Steel and fiber combination rope where the fiber is an integral load bearing member.

High strength confirmed by bridon s powercheck testing of a sample.

Constructex constructex is produced by rotary swaging a completed rope after manufacture.

Excellent service life in the most demanding applications.

Superior abrasion and crushing resistance makes constructex the ideal rope for these applications.

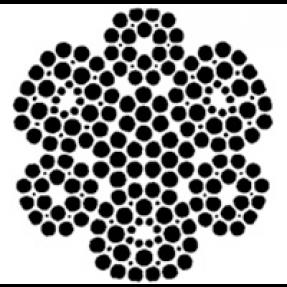

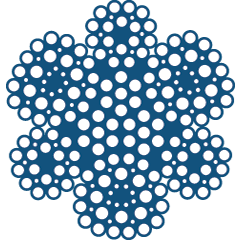

Bridon constructex is nine strand rope made up of three different strand constructions.

Let us help you download brochure.

High performance crane ropes rotary hammer swaged effect for maximum resistance to damage exceptional service life in the most demanding applications robust construction high breaking force excellent crush resistance high quality performance wire ropes for the lifting industry.

Robust crush resistant rope construction.

Each outside strand manufactured with a soft plastic center.

Call bc wire rope bridon constructex is recommended as a drill line tubing line and boom hoist rope where longer service life is desired.

Bridon constructex wire rope nine strand rope made up of three different strand constructions.

Each outside strand manufactured with a soft plastic center.

Constructex is produced by rotary swaging a completed rope after manufacture.

Horizon energy rig 16 had been running 10 parts of 1 1 4 6x19 eips iwrs rrl drilling line with a ton mile goal of 15 at between 1200 1500 ton miles since last cut.

As strong and robust as a steel rope but lighter with superior bending fatique life.

High strength confirmed by bridon s powercheck testing of a sample.

The team at horizon energy saw the value of replacing the standard drill line with bridon american s constructex a rope with greater strength abrasion and crush resistance.

Constructex can be recommended with confidence wherever abusive conditions exist particularly where the rope is retired because of broken wires resulting from wear and rushing on the drum.

The core is a wire rope with a central king wire that runs parallel to the length of the rope.

This swaging process reduces the rope diameter and reforms the profile of the outer strands providing a rope that performs excellently in multilayer drum applications.